HDL Series

Search RCF products

Choose search system

Search Product

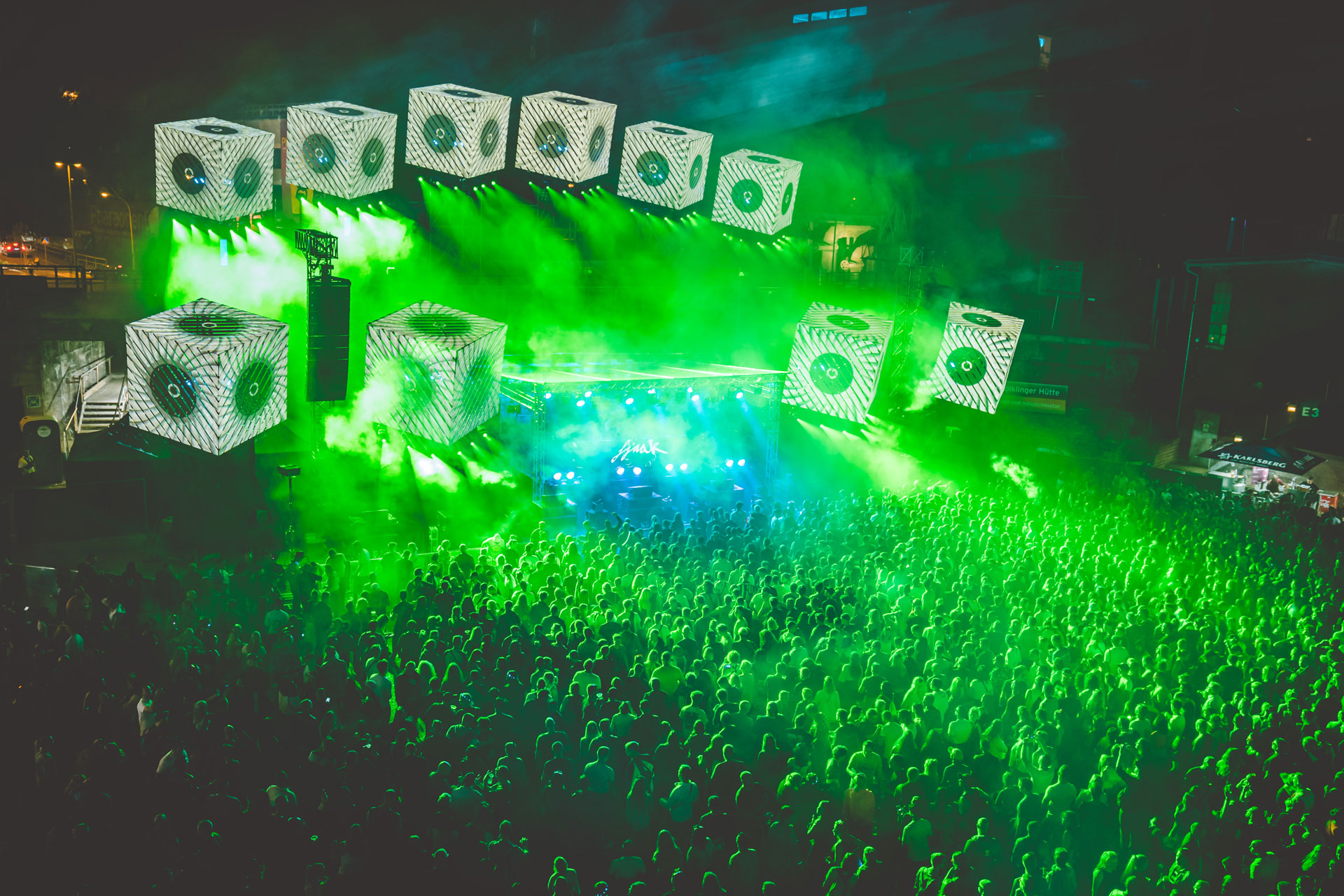

When searching for a new touring sound system there are essential prerequisites: higher SPL’s, constant directivity and sonic excellence. In today’s competitive world rental companies are looking for more, such as reduced weight, speed of rigging/derigging and ease of transportation. And once the system is in the air, with ever decreasing venue prep times, speed of optimisation using the inherent management software is vital.

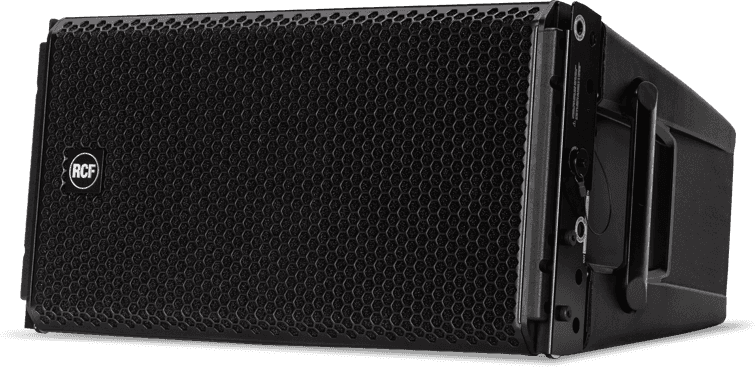

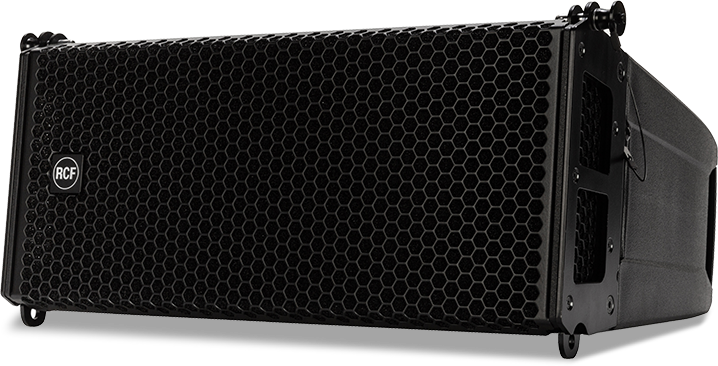

The HDL System is changing the concept of large format arrays, providing first class performance to an extended market of professional users.

Why active?

The HDL System is composed of HDL 30-A and HDL 50-A, equipped with modern and innovative technology. Each component has been consistently and specially developed by RCF’s experienced engineering teams, with all components carefully matched to each other. This complete integration of all components allows not only superior performance and maximum operational reliability, but also provides users easy handling and plug & play comfort. Besides this important fact, active speakers offer valuable advantages: while passive speakers often need long cable runs, the energy loss due to the cable resistance is a huge factor. This effect is irrelevant in powered speakers where the amplifier is just a couple of centimeters away from the transducer. An active sound reinforcement system means more than just having amplifiers packed into a speaker housing. The real innovation is when each single component is controlled by individual DSP settings. Scaling a line array is the most important aspect when talking about best performance and coverage. Where passive systems have limits in impedance load or number of amplifier channels, an active RCF sound system is freely scalable and individually controllable. Having an HDL system gives you the freedom to work at many different locations with the same system, merely changing the number of modules.

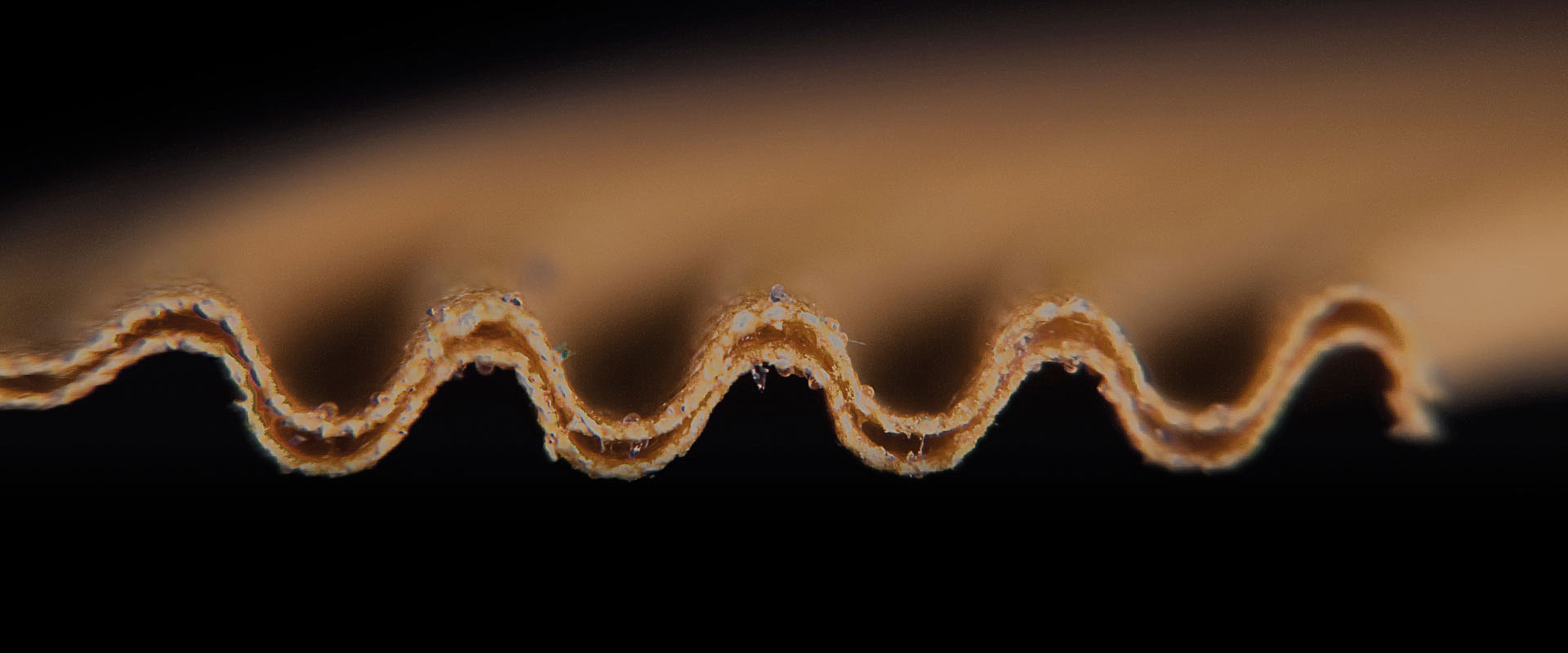

The transducers innovators

The RCF loudspeaker line incorporates a vast range of transducers covering the entire audio spectrum. We design our transducers to optimise the relationship between the purity of sound, combining the absence of distortion and the ability to withstand high power levels over a long period of time. RCF develops advanced transducer technology including the application of high-tech materials such as Neodymium, Carbon Fibre, Pure Titanium, Kevlar, Kapton and Mylar hybrids. With over 70 years of design and manufacturing experience in the market, RCF has been instrumental in technological inventions such as: carbon fibre cone moulding, double silicon spiders, inside/outside voice coil windings to edge wound voice coil manufacturing and pure titanium diaphragm forming. Our latest developments have resulted in designing state of the art neodymium magnetic circuits, radically new voice coil ventilation systems and ground breaking direct drive voice coil assemblies.