RCF Precision Transducers

Innovacción en transductores

RCF boasts over 75 years of experience in designing and manufacturing transducers, with a particular focus on moving coil loudspeakers. Our transducers are engineered to optimize the balance between power delivery and sound purity, achieving minimal distortion and the capacity to endure high power levels for extended periods.

Manejo de potencia

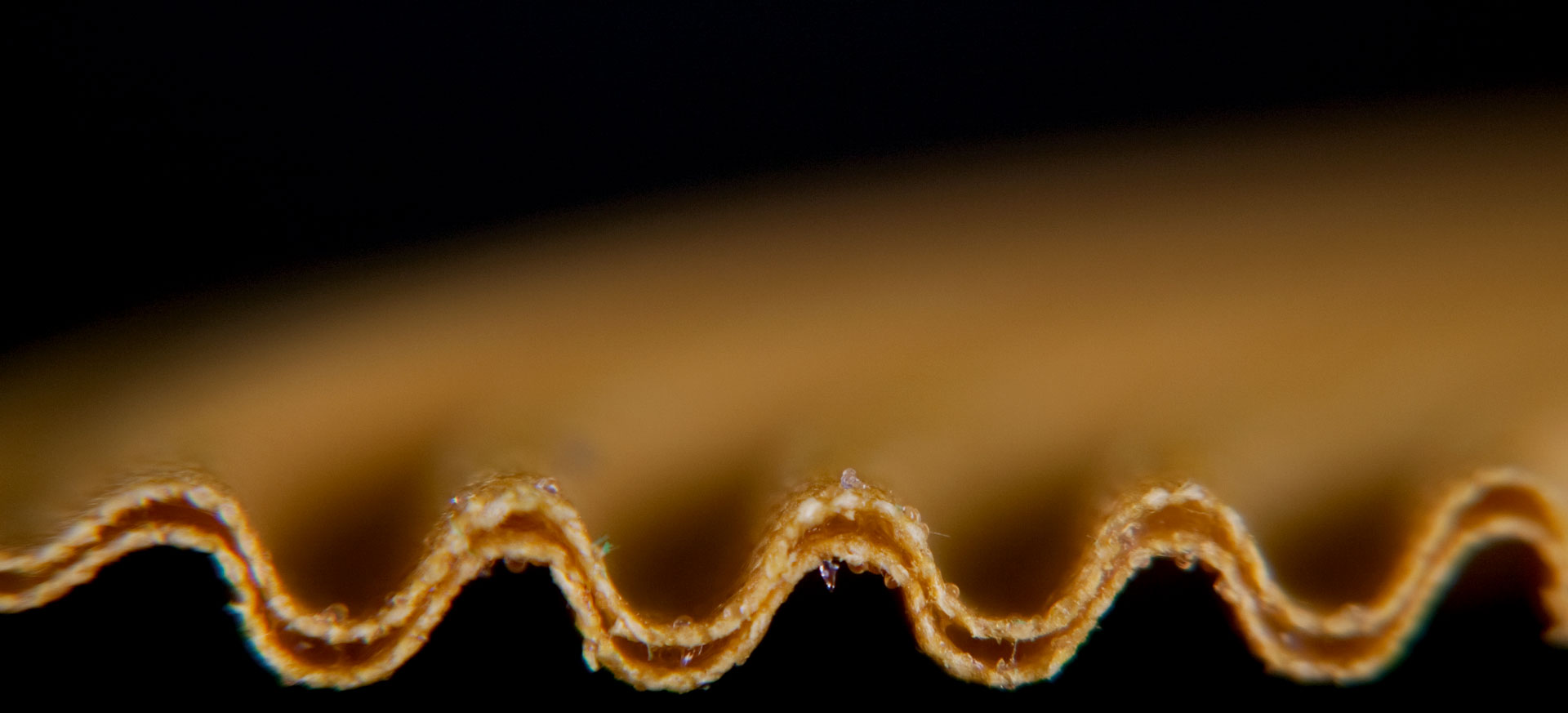

En el corazón del diseño de los nuevos transductores RCF hay grandes cantidades de tiempo y recursos invertidas en ciencia de materiales, investigación en topología de diseño y pruebas de potencia para desarrollar productos estructuralmente muy resistentes, con características térmicas óptimas y el mejor manejo de potencia. Los ingenieros de RCF Precision han desarrollado un material de poliimida capaz de aguantar temperaturas de hasta 380 °C, que va más allá de los requerimientos térmicos de los sistemas profesionales modernos de sonido. La combinación de este material con adhesivos especiales, nuestra tecnología de bobinas interiores y exteriores, las arañas dobles de silicona, la hiperventilación forzada doble y los conos hechos con un tratamiento de fibra especial hacen que la familia de productos RCF tenga los transductores más resistes y fiables de la industria.

Manejo de potencia

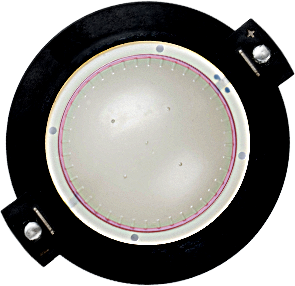

High-Class Neodymium: Best-in-Class Magnets

Neodymium, a rare earth material, enhances efficiency, power handling, and weight reduction. Our designs, with a 20% stronger magnetic field than typical neodymium grades, enable precise voice coil control and higher force levels (BL). Magnet geometry and configuration are optimized for maximum flux density, incorporating thermal management to ensure reliability. Techniques such as computer-aided magnet optimization and FEM analysis refine magnet weight, flux density, and field saturation, significantly reducing driver weight and harmonic distortion.

The T-pole design minimizes flux modulation in the magnetic assembly during typical voice coil movements within the gap. A specially designed copper ring, pressed onto the pole piece, modifies and reduces the magnetic circuit and voice coil inductance, enabling a controlled extension of the acoustic frequency response.

The T-pole design minimizes flux modulation in the magnetic assembly during typical voice coil movements within the gap. A specially designed copper ring, pressed onto the pole piece, modifies and reduces the magnetic circuit and voice coil inductance, enabling a controlled extension of the acoustic frequency response.

Neodymium, a rare earth material, enhances efficiency, power handling, and weight reduction. Our designs, with a 20% stronger magnetic field than typical neodymium grades, enable precise voice coil control and higher force levels (BL). Magnet geometry and configuration are optimized for maximum flux density, incorporating thermal management to ensure reliability. Techniques such as computer-aided magnet optimization and FEM analysis refine magnet weight, flux density, and field saturation, significantly reducing driver weight and harmonic distortion.

The T-pole design minimizes flux modulation in the magnetic assembly during typical voice coil movements within the gap. A specially designed copper ring, pressed onto the pole piece, modifies and reduces the magnetic circuit and voice coil inductance, enabling a controlled extension of the acoustic frequency response.

The T-pole design minimizes flux modulation in the magnetic assembly during typical voice coil movements within the gap. A specially designed copper ring, pressed onto the pole piece, modifies and reduces the magnetic circuit and voice coil inductance, enabling a controlled extension of the acoustic frequency response.

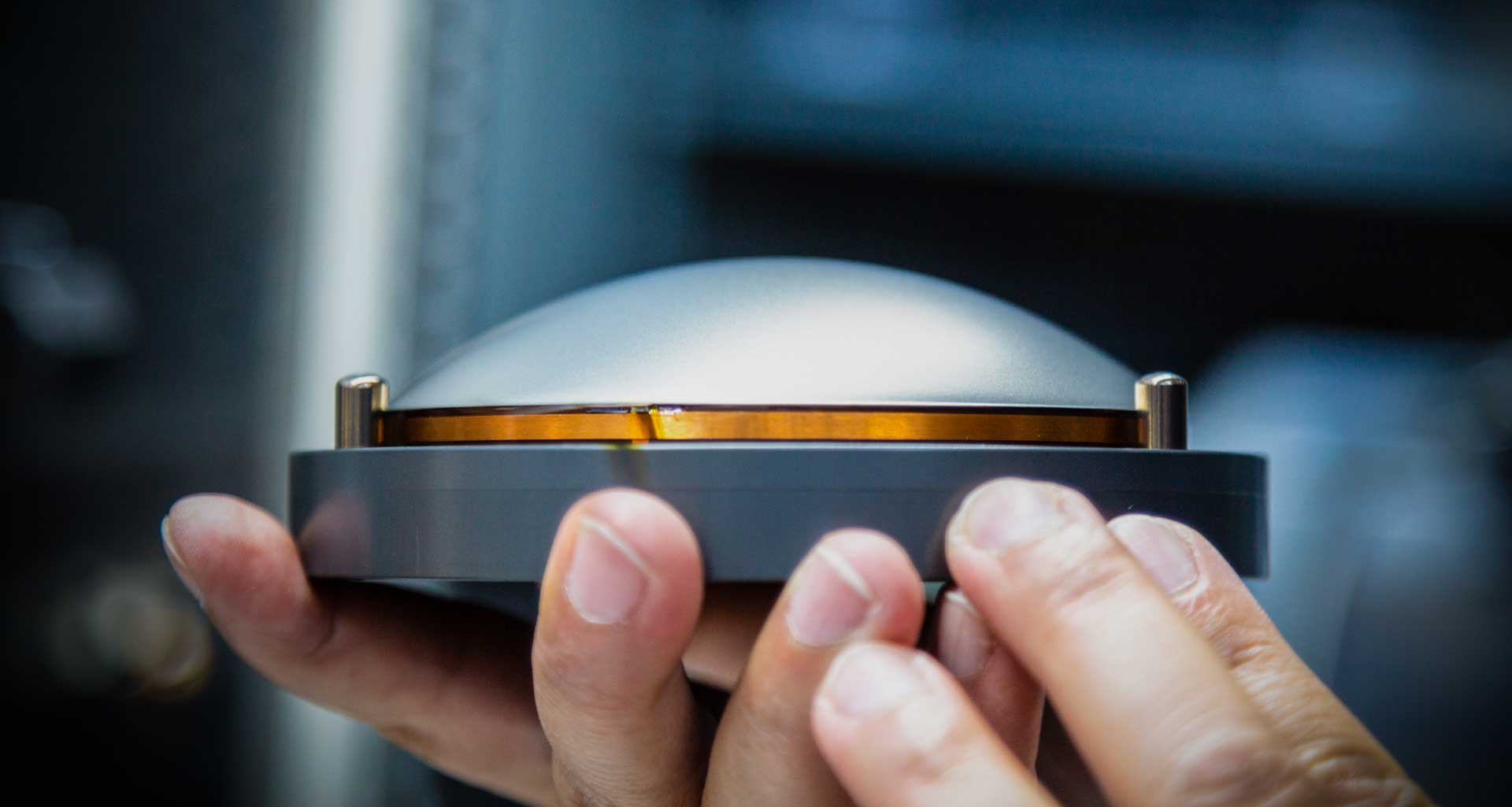

Sistemas dobles hyper-vented

Our cooling designs combine various components to create an ideal ventilation system. The RCF engineering team emphasizes finned cooling channels and optimizes the surface area of the front magnetic plate for efficient heat dissipation. The double silicone sealed spider design functions as an air pump, expelling hot air and drawing in fresh air with each movement of the cone assembly.